Single Cylinder Solution

First, consider a single unconstrained thick-walled cylinder under pressure loading as shown in

Figure 11 below. The objective is to determine the stresses, strains, and deflections throughout

the cylinder.

Figure 11. Thick-Walled Cylinder Under Internal and External Pressure Loading

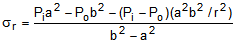

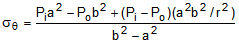

The linear solution to this problem is attributed to the French mathematician Gabriel Lame' in

1833. According to his solution, the radial and hoop stresses at any radial location, r, are given by

the following formulas:

(1a)

(1a)

(1b)

(1b)where,

sr = radial stress

sq = hoop stress

r = radius

a = inner radius

b = outer radius

Pi = internal pressure

Po = external pressure

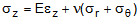

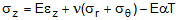

In addition, if the cylinder is fully or partially constrained axially then a uniform axial stress also

develops which is given by,

(1c)

(1c)where,

sz = axial stress

E = tensile modulus

n = Poisson ratio

ez = applied axial strain (zero if fully constrained)

If the cylinder is unconstrained then sz = 0 and the induced axial strain is given by,

Eqns. 1a-1c are commonly referred as the Lame' equations and are the foundation for the Concyl

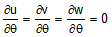

solution algorithm. The derivation of Lame's equations requires the standard application of force

equilibrium equations, linear strain-displacement relations, and isotropic Hookean constitutive

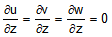

relations, all in polar coordinates. We will make use of the same strain-displacement and

constitutive relations in the Concyl algorithm derivation that follows. The linear strain-

displacement relations in polar coordinates for a generalized plane strain axisymmetric problem

are

(2a)

(2a) (2b)

(2b) , from generalized plane strain (2c)

, from generalized plane strain (2c) , from generalized plane strain (2d)

, from generalized plane strain (2d) , from axisymmetry (2e)

, from axisymmetry (2e)where,

er = radial strain

eq = hoop strain

ez = axial strain

u = radial deflection

v = hoop deflection

w = axial deflection

r = radial direction

q = hoop direction

z = axial direction

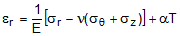

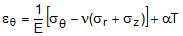

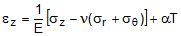

The 3D constitutive relations for an isotropic Hookean material can be expressed as

(3a)

(3a) (3b)

(3b) (3c)

(3c)where,

a = coefficient of thermal expansion

T = temperature difference relative to To

To = stress-free temperature

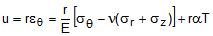

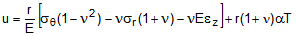

Eqn. (3c) can be rearranged as

(4)

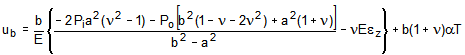

(4)Substituting Eqn. (3b) into Eqn. (2b) yields the following formula for the radial displacement:

(5)

(5)Substituting Eqn. (4) into Eqn. (5) yields

(6)

(6)Eqn. (6) gives the radial displacement throughout the cylinder in terms of the radial stress and

hoop stress. The radial and hoop stresses are given by the Lame' equations. Substituting Eqns.

(1a) and (1b) into Eqn. (6) gives the following formulas for the radial displacement at the inner and

outer surfaces of the cylinder.

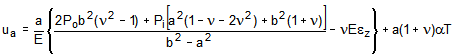

(7a)

(7a) (7b)

(7b)where,

ua = inner radial deflection

ub = outer radial deflection

Multi-Cylinder Solution

Extension of the single cylinder solution to a system of concentric bonded cylinders begins by

enforcing the kinematic compatibility constraint at the interface between each cylinder. The outer

radial deflection of any cylinder must equal the inner radial deflection of the cylinder that is bonded

to its outer surface. This statement leads to the equation

, i = 1, N-1 (8)

, i = 1, N-1 (8)for each pair of bonded cylinders, where i is the cylinder number starting at 1 for the innermost

cylinder and ending at N for the outermost cylinder. Figure 12 below shows the cylinder and

interface numbering scheme for a system of five cylinders. Note that the i in Eqn. (8) goes from

1 to N-1 because the inner surface of cylinder 1 is a free surface, as is the outer surface of

cylinder N.

Figure 12. Cylinder and Interface Numbering Scheme

Next, consider a system with only two bonded cylinders. The interfaces will then be numbered

from 1 to 3, and the cylinders numbered from 1 to 2. The i in Eqn. (8) will go from 1 to 1, which

means only a single equation is needed to represent the system. Substituting Eqns. (7a) and (7b)

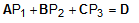

into Eqn. (8) and collecting like coefficients for the interface pressure terms yields an equation

with the following form:

(9)

(9)where the subscripts denote the interface numbers. Since interfaces 1 and 3 are free surfaces,

the values of P1 and P3 are given as input. Therefore, only P2 is unknown, and Eqn. (9) can be

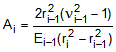

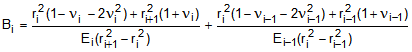

readily solved. The values of A, B, C, and D in the Eqn. (9) are as follows:

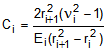

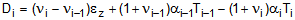

(10a)

(10a) (10b)

(10b) (10c)

(10c) (10d)

(10d)with i ranging from 2 to N, where N is the total number of cylinders. The i subscript on the radius

denotes the radial interface number. The i subscript on the material properties (E,n,a,T)

denotes

the cylinder number. The interfaces and cylinders are numbered in accordance with the

numbering scheme shown in Figure 10.

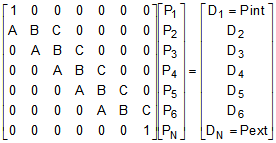

Extending the solution to an arbitrary number of cylinders results in the following tridiagonal

system of equations with one row for each interface:

(11)

(11)

The first and last rows have the internal and external pressure boundary conditions. This system

of equations can be readily solved using Gauss elimination to yield all of the unknown interface

pressures between the cylinders. Once these interface pressures are known, then they can be

substituted back into the Lame' equations [Eqn. (1)] to determine the stresses throughout each

cylinder at any arbitrary radius. The stresses can then be used to compute the corresponding

strains using the constitutive relations [Eqn. (3)]. Finally, the radial displacements can computed

from the strains using the strain-displacement relations [Eqn. (2)].

Program Flow

The Concyl solver does the following steps:

1. Read input file

2. Build system equations

3. Solve for unknown interface pressures

4. Compute stresses

5. Compute strains

6. Compute displacements

7. Compute strain energies

8. Write output files

If an optimizer run is requested, then the specified input parameter is varied within the specified

range, and the above steps are repeated to compute the specified solution quantity as a function

of the specified input parameter. If a single optimum value of the input parameter is requested,

then a bisection search is done to find the optimum value. If no optimum solution can be found

within the specified range of input values, then an error message is displayed.

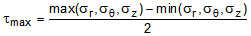

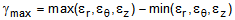

Maximum Shear

The maximum shear stresses and strains are computed from the formulas,

(12a)

(12a) (12b)

(12b)where,

tmax = maximum shear stress

gmax = maximum engineering shear strain

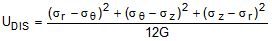

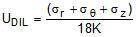

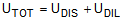

Strain Energy

The strain energy results are computed from the formulas,

(13a)

(13a) (13b)

(13b) (13c)

(13c)where,

UDIS = distortional strain energy

UDIL = dilatational strain energy

UTOT = total strain energy

G = shear modulus

K = bulk modulus

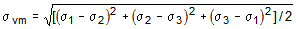

Equivalent (Von-Mises) Stress

Von-Mises or equivalent stress is commonly used as the yield failure criterion for ductile metals. It

is given by the formula,

(14)

(14)where,

= von-mises stress

= von-mises stress = principal stresses (

= principal stresses ( )

)Comparison of Eqn. (14) and Eqn. (13a) shows that the von-mises stress is proportional to the

square root of the distortional strain energy [Eqn. (13a)] in accordance with the following relation:

(15)

(15)Concyl computes von-mises stress and does save it to the output and plot files. However, the

GUI cannot yet display von-mises stress results.