|

1. Shrink-Fit Pipe Under Thermal And Pressure Loading

|

Previous Next

|

1.1. Problem Description

Consider a long thick-walled pipe with two material layers as shown in Figure 1.1. The inner layer is made

of lead with an inner radius 1.00 in. and an outer radius of 1.25 in. at a temperature of 77°F. The outer

layer is steel with an inner radius of 1.25 in. and an outer radius of 1.50 in. at a temperature of 250°F. The

two layers are joined by a shrink-fit once the outer layer has cooled to the same temperature as the inner

layer.

The pipe assembly is designed to carry a radioactive fluid over a range of pressures and temperatures.

Figure 1.1 shows the pipe cross section dimensions prior to the shrink-fit assembly. Table 1.1 lists the

material properties for each layer, and Table 1.2 gives the loading requirements. The thermal loading is

uniform with no temperature variation through the pipe thickness. Also, the pipe is fully constrained axially

so that the axial strain is zero.

Figure 1.1. Dual-Layer Pipe Geometry (Stress Free)

Table 1.1 Material Properties

|

Material

|

Designation

(Reference)

|

Tensile

Modulus (psi)

|

Poisson

Ratio

|

CTE

(/°F)

|

Ref. Temp.

(°F)

|

Density.

(lb/in3)

|

|

Lead

|

Lead

(wikipedia.com)

|

2.32e6

|

0.44

|

1.61e-5

|

77

|

0.410

|

|

Steel

|

301 Stainless

(MIL-HDBK-5H)

|

28e6

|

0.27

|

8.55e-6

|

250

|

0.286

|

Table 1.2. Loading Requirements

|

Pressure

(psi)

|

Temperature

(°F)

|

Axial Constraint

|

|

100 to 1000

|

-25 to 200

|

Full (ez = 0)

|

1.2. Objectives

1. Use Concyl to determine the following:

a. The initial radial overlap between the pipe layers at room temperature (77°F) prior to assembly.

b. The interface pressure between the pipe layers at room temperature after assembly (thermal

loading only).

c. The maximum tensile stresses and strains in each layer at the upper and lower pressure and

temperature limits.

d. The critical low temperature for layer separation at the lower and upper pressure limits.

2. Use finite-element analysis (FEA) to verify the Concyl results.

1.3. Key Assumptions

1. Linear, elastic, and isotropic materials

2. Linear kinematics

3. Uniform thermal loading (no

temperature variation in any direction)

4. Plane strain in axial direction

5. Perfectly bonded cylinders (no sliding at interfaces)

1.4. Concyl Analysis

Concyl can readily meet all four of the above objectives (1a through 1d). The first objective, however, can

be answered using elementary formulas without the use of any numerical tools. The remaining objectives

are a little more difficult and do require either an exact numerical tool such as Concyl or an approximate

numerical approach, such as the finite element method.

Five load cases were analyzed here to consider all the possible permutations of applied temperature and

pressure in accordance with the loading requirements listed in Table 1.2. Load case 1 gives the results

needed to satisfy objectives 1a and 1b. The other load cases provide the results needed determine the

overall peak stresses and strains for objective 1c. Objective 1d was answered using the Concyl optimizer

to determine the critical temperature for a zero interface pressure between the cylinders at the upper and

lower pressure limits.

Table 1.3. Load Cases

|

Case

|

Pressure

(psi)

|

Temperature

(°F)

|

|

1

|

0

|

77

|

|

2

|

100

|

-25

|

|

3

|

1000

|

-25

|

|

4

|

100

|

200

|

|

5

|

1000

|

200

|

1.4.1. Radial Overlap

The first objective for this problem is to determine the radial interference between the layers at room

temperature. This can be readily done using the dimensions in Figure 1.1 and the material properties in

Table 1.1 together with some basic formulas. For small strains and small rotations the hoop strain is

related to the radial deformation by the equation,

(1.1)

(1.1)where,

eh = hoop strain

Dr = radial growth (Dr = rf - r)

rf = final radius

r = initial radius (stress-free)

For a linear isotropic material the strain induced by thermal loading is equal in all directions and is given by,

(1.2)

(1.2)where,

a = coefficient of thermal expansion (CTE)

DT= temperature relative to the stress-free temperature (DT = T - T0)

T = applied temperature

T0 = stress-free temperature

Combining Eqns. 1.1 and 1.2 yields the following formula for the radial growth within each layer as a

function of temperature:

(1.3)

(1.3)Considering a temperature of 77°F and using the values from Figure 1.1 and Table 1.1, the following values

of Dr at the interface are computed:

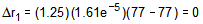

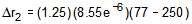

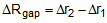

Inner Layer:

Outer Layer:  =

-0.00185

=

-0.00185 Since the inner layer reference temperature is 77 F, the induced thermal strain is zero which means no

radial growth. The radial gap between the layers is then given by

= -0.00185 ¬¾¾ Radial Overlap at 77°F (1.4)

= -0.00185 ¬¾¾ Radial Overlap at 77°F (1.4)where a positive value denotes a gap and a negative value denotes an interference. In this case we have a

radial overlap at room temperature that is slightly less than 2 mils. That is how much the inner radius of the

steel layer would decrease (stress free) if it were to cool to 77°F in the absence of the inner layer.

However, the presence of the inner layer will result in a contact pressure between the two layers as the

outer layer shrinks against the inner layer. This contact pressure joins the layers together and induces

stresses in each layer.

1.4.2. Interface Pressure

The Concyl results for load case 1 give the interface pressure between the layers at room temperature.

The Concly input and output for load case 1 are provided in Listing 1.1a and Listing 1.1b at the end of this

report. Concyl computes an interface pressure of 1247 psi for the unpressurized pipe at 77°F.

1.4.3. Maximum Stresses and Strains

The Concyl results for load cases 2 through 5 give the stresses and strains in each layer under the required

operational pressure and temperature limits. Table 1.4 lists the maximum tensile hoop stresses and strains

in each layer along with the interface pressure (radial stress) for each load case. The maximum stress

location within each layer is also indicated by an I (inner) or O (outer). This table shows that the lead layer

remains in compression with a negative hoop strain for all load cases. The steel layer remains in tension

for all load cases, even though the corresponding hoop strains are negative for load cases 1 through 3.

Table 1.4. Concyl Stress and Strain Results

|

|

|

Hoop Stress / Strain (psi / %)

|

|

Case

|

Interface Pressure

(psi)

|

Inner Layer

|

Outer Layer

|

|

1

|

1247

|

-5682 / -0.1634 (O)

|

6916 / -0.0155 (I)

|

|

2

|

494

|

-1897 / -0.1247 (O)

|

2742 / -0.0538 (I)

|

|

3

|

1233

|

-2061 / -0.1102 (O)

|

6838 / -0.0393 (I)

|

|

4

|

2336

|

-10.28e3 / -0.2066 (O)

|

12.95e3 / 0.0342 (I)

|

|

5

|

3074

|

-10.45e3 / -0.1921 (O)

|

17.05e3 / 0.0487 (I)

|

The maximum tensile stress that occurs throughout the required pressure and temperature ranges is 17.05

ksi, and the corresponding maximum strain is 0.0487%. These both occur at the inner surface of the steel

layer for load case 5. Table 1.5 gives a summary of the pipe stress analysis results computed from Concyl.

Table 1.5. Concyl Result Summary

|

Condition

|

Value

|

Load Case

|

Temp. (°F)

|

Press. (psi)

|

|

Min. Interface Pressure

|

464

|

2

|

-25

|

100

|

|

Max. Interface Pressure

|

3074

|

5

|

200

|

1000

|

|

Max. Tensile Stress

|

17.05e3

|

5

|

200

|

1000

|

|

Max. Tensile Strain

|

0.0487

|

5

|

200

|

1000

|

Figure 1.2 shows a plot of the four stress components versus radius for load case 1. Note that all of the

stress components, except for the radial stress, have a step discontinuity at the material interface. This is

to be expected since each layer is a different material, and the induced stresses for this load case are

highly dependent on the material properties. However, the plot of radial stress, which is shown in Figure

1.3, must be continuous, and the radial stress value at the layer interface must be equal in both materials to

enforce static equilibrium. The first derivative in Figure 1.3 is discontinuous, as expected, and shows the

peak compressive interface pressure of 1247 psi which agrees with the value listed in Table 1.4.

Figure 1.4 shows how the radial strain varies with radius. All four of the strain components have step

discontinuities. This means that the first derivative of the strain with respect to radius is infinite at the

material interface. This is to be expected when thermal loading is applied since these strain values are

mechanical strains, not total strains.

Figure 1.5 shows the radial displacement variation through the pipe. This plot must be continuous to

enforce displacement compatibility at the interface. If it were discontinuous, then a crack or overlap at the

interface would be indicated. The radial displacement is negative throughout the pipe. This is expected

since the applied thermal strain is negative and there is no internal pressure loading.

Figure 1.2. Stress Versus Radius For Load Case 1

Figure 1.3. Radial Stress Versus Radius For Load Case 1

Figure 1.4. Strain Versus Radius For Load Case 1

Figure 1.5. Radial Displacement Versus Radius For Load Case 1

Figures 1.6 through 1.9 show plots of the Concyl results for load case 5. This load case has a 200°F

thermal load combined with a 1000 psi internal pressure load. These plots show that the steel layer carries

all the tension load from the applied pressure, while the inner lead layer remains in compression. The

results also show that the inner layer has much greater strain magnitudes because of the softer lead.

Figure 1.9 shows that for this particular load case, positive radial displacement is predicted near the

material interface, but the radial displacement is negative elsewhere.

Figure 1.6. Stress Versus Radius For Load Case 5

Figure 1.7. Radial Stress Versus Radius For Load Case 5

Figure 1.8. Strain Versus Radius For Load Case 5

Figure 1.9. Radial Displacement Versus Radius For Load Case 5

1.4.4. Critical Temperature

Determining the critical low temperature that would cause a loss of compression between the layers was

very straightforward using the Concyl optimizer. The applied temperature was specified as the input

parameter, and the radial stress between the cylinders was specified as the output parameter. The desired

optimum value for the radial stress was entered as zero. The lower and upper limits for the temperature

search range were specified as -200°F and 0°F respectively. One optimization run was done at the low

pressure limit of 100 psi, and another run was done at the high pressure limit of 1000 psi. The Concyl

optimization input file for the low pressure run is shown in Listing 1.2. Table 1.6 gives the results from the

optimization runs. Figure 1.10 shows a plot of the interface pressure as a function of temperature at

operational pressure of 100 psi and 1000 psi.

Table 1.6 Concyl Optimizer Results

|

Pressure

|

Critical

Temperature

(°F)

|

|

100

|

-85.4

|

|

1000

|

-175.7

|

Figure 1.10. Interface Pressure Versus Temperature

1.5. Finite Element Analysis

Confirmation of the Concyl results was done with two different FEA programs: NISA and TEXLESP2D.

NISA is a commercial general purpose FEA program that is described in Ref. 1. TEXLESP2D is a

specialized NASA program developed for nonlinear 2D stress analysis (Ref. 2). A single finite element

model was made for use with both programs. Five runs were done to analyze the load cases listed in Table

1.3. In addition, another set of runs was done to verify the critical temperature calculations that were done

by the Concyl optimizer. This gives two more load cases with the loads listed in Table 1.6. Load case 6

has an applied pressure of 100 psi, and load case 7 has an applied pressure of 1000 psi.

1.5.1. Model Description

The FEA stress analysis was done with the small 2D model shown in Figure 1.11. The model is

axisymmetric with 100 quadratic isoparametric elements. Since this problem has no axial stress variation,

only one element is required in the axial direction. Figure 1.11 shows the finite element mesh with each

material a different color. Each cylinder has 50 equally spaced elements in the radial direction. This figure

also shows the applied pressure and displacement boundary conditions (BC's).

The NISA and TEXLESP2D programs differ in the way that thermal loading is applied to the model. NISA

has a single stress-free temperature for the entire model, and temperature BC's are applied to the nodes.

TEXLESP2D assigns a stress-free temperature to each material, and a uniform temperature is applied to

the entire model. Listing 1.3 at the end of this report shows the NISA input file for load case 5, and Listing

1.4 shows the corresponding TEXLESP2D input file.

Figure 1.11. Finite Element Mesh and Boundary Conditions

1.5.2. NISA Results

Table 1.7 shows the NISA interface pressures for all the load cases. These values are in close agreement

with the exact Concyl results listed in Table 1.4. The maximum error in the NISA results is less then 3%

which is generally very good for a finite element model. Also, the interface pressures for load cases 6 and

7 are very close to zero as expected.

Table 1.7. NISA Interface Pressure Results

|

Case

|

Interface Pressure

(psi)

|

Error (%)

|

|

1

|

1228

|

-1.52

|

|

2

|

482

|

-2.43

|

|

3

|

1217

|

-1.29

|

|

4

|

2321

|

-0.642

|

|

5

|

3026

|

-1.56

|

|

6

|

3.47

|

small

|

|

7

|

3.95

|

small

|

1.5.3. TEXLESP Results

Table 1.8 shows the TEXLESP interface pressures for all the load cases. These values are in close

agreement with the exact Concyl results listed in Table 1.4. The maximum error in the TEXLESP results is

less then 1%. Also, the interface pressures for load cases 6 and 7 are very close to zero as expected.

These results show that for this particular problem TEXLESP has less error than NISA.

Table 1.8. TEXLESP Interface Pressure Results

|

Case

|

Interface Pressure

(psi)

|

Error (%)

|

|

1

|

1241

|

-0.481

|

|

2

|

492

|

-0.405

|

|

3

|

1227

|

-0.487

|

|

4

|

2325

|

-0.471

|

|

5

|

3060

|

-0.455

|

|

6

|

0.293

|

small

|

|

7

|

0.194

|

small

|

1.6. Conclusions

This example demonstrates how to use Concyl to analyze a shrink-fit compound cylinder problem involving

combined thermal and pressure loading. Use of the Concyl optimizer was also demonstrated. The Concyl

results have good agreement with the results from two separate FEA programs. This verifies that Concyl is

an accurate and efficient tool for compound cylinder stress analysis.

References

2. "TEXLESP-2D Users Manual", Eric B. Becker, et al, NASA MSFC-RPT-1564, 1988.

Concyl Listings

Listing 1.1a. Concyl Input For Load Case 1

|

!Concyl Input File

Load Case 1: P=0, T=77

2

2

1, 1.25, 1.5

1, 77

2, 250

1, Lead, 2.32e+006, 0.44, 1.61e-005, 0.41

2, Steel, 2.8e+007, 0.27, 8.55e-006, 0.286

0, 0

77

0

1

ALL

10

|

Listing 1.1b. Concyl Output For Load Case 1

|

------------------------------------------------------

Output Data

------------------------------------------------------

---------------------

Interface Pressures

---------------------

Interface Radius Pressure

--------- ------ --------

1 1.0000 +0.00000

2 1.2500 +1247.2

3 1.5000 +0.00000

Note: Negative pressure means tension

-----------------------------

Cylinder Interface Stresses

-----------------------------

Cyl<Int> SIGH SIGR SIGZ TAUMAX SIGE

-------- ---- ---- ---- ------ ----

1I -6928.8 +0.00000 -3048.7 +3464.4 +6014.9

1O -5681.6 -1247.2 -3048.7 +2840.8 +3862.8

--------------------------------------------------------------------------------

2I +6916.2 -1247.2 +42947. +22097. +40731.

2O +5669.0 +0.00000 +42947. +21473. +40412.

--------------------------------------------------------------------------------

-----------------------------------------

Cylinder Interface Strains (Mechanical)

-----------------------------------------

Cyl<Int> EPSH EPSR EPSZ GAMMAX EPSE

-------- ---- ---- ---- ------ ----

1I -0.0024084 +0.0018923 +0.00000 +0.0043006 +3048.7

1O -0.0016342 +0.0011182 +0.00000 +0.0027524 +3048.7

--------------------------------------------------------------------------------

2I -0.00015510 -0.00052536 +0.0014791 +0.0020045 +42947.

2O -0.00021166 -0.00046880 +0.0014791 +0.0019479 +42947.

--------------------------------------------------------------------------------

------------------------------------

Cylinder Interface Strains (Total)

------------------------------------

Cyl<Int> EPSHT EPSRT EPSZT GAMMAX

-------- ----- ----- ----- ------

1I -0.0024084 +0.0018923 +0.00000 +0.0043006

1O -0.0016342 +0.0011182 +0.00000 +0.0027524

------------------------------------------------------------------

2I -0.0016342 -0.0020045 +0.00000 +0.0020045

2O -0.0016908 -0.0019479 +0.00000 +0.0019479

------------------------------------------------------------------

------------------------------------

Cylinder Interface Strain Energies

------------------------------------

Cyl<Int> Distortion Dilatation Total

-------- ---------- ---------- -----

1I +7.4854 +0.85819 +8.3436

1O +3.0871 +0.85819 +3.9453

------------------------------------------------

2I +25.082 +6.4715 +31.554

2O +24.691 +6.4715 +31.162

------------------------------------------------

-------------------------

Interface Displacements

-------------------------

Interface Radius DispR

--------- ------ -----

1 1.0000 -0.0024084

2 1.2500 -0.0020428

3 1.5000 -0.0025362

|

Listing 1.2. Concyl Input For Optimization Run

|

!Concyl Input File

Optimization Run: Invar=Temp, OutVar=SIGR, P=100

2

2

1, 1.25, 1.5

1, 77

2, 250

1, Lead, 2.32e+006, 0.44, 1.61e-005, 0.41

2, Steel, 2.8e+007, 0.27, 8.55e-006, 0.286

100, 0

0

0

1

ALL

10

1

7

0

1

2

-200, 0

0

|

Listing 1.3. NISA Input For Load Case 5

***********************************************************************

*** CONCYL SAMPLE 1:

*** Compound Cylinder Under Thermal and Pressure Load

***********************************************************************

ANALYSIS = STATIC

SOLVER = FRONTAL

NODE = OFF

ELEMENT = OFF

FILE = result

SAVE = 26,27

SORT = 20

*TITLE

Concyl Sample 1

Compound Cylinder Under Thermal and Pressure Loading

*ELTYPE

1, 3, 2

*NODES

1,,,, 1.00000E+00, 0.00000E+00, 0.00000E+00, 0

2,,,, 1.00500E+00, 0.00000E+00, 0.00000E+00, 0

...

502,,,, 1.49500E+00, 5.00000E-03, 0.00000E+00, 0

503,,,, 1.50000E+00, 5.00000E-03, 0.00000E+00, 0

*ELEMENTS

1, 100, 1, 1, 0

1, 103, 2, 204, 53, 153, 52,

203,

...

100, 200, 1, 1, 0

302, 403, 303, 503, 353, 453, 352, 502,

*MATERIAL

***--------------------------------------------------------------------------

*** Inner Layer, Lead

***--------------------------------------------------------------------------

EX , 100,0, 2.32e6

NUXY, 100,0, 0.44

DENS, 100,0, 0.410

ALPX, 100,0, 1.61e-5

***--------------------------------------------------------------------------

*** Outer Layer, 301 Stainless Steel

***--------------------------------------------------------------------------

EX , 200,0, 27e6

NUXY, 200,0, 0.27

DENS, 200,0, 0.286

ALPX, 200,0, 8.55e-6

*SETS

***--------------------------------------------------------------------------

*** node sets for stress/strain recovery

***--------------------------------------------------------------------------

100,S, 1, 52, 203,

200,S, 51, 102, 253,

300,S, 303, 353, 503,

***--------------------------------------------------------------------------

*** elements sets for stress/strain recovery

***--------------------------------------------------------------------------

400,S, 1, 50, 51, 100

***--------------------------------------------------------------------------

*** load case 1: thermal load at 77 degrees with no pressure

***--------------------------------------------------------------------------

*LDCASE, ID= 1

1, 1, 7, 1, 4, 4, 1, 77.0, .000

*LCTITLE

Temperature = 77, Pressure = 0

*ECHO = OFF

*SPDISP

***--------------------------------------------------------------------------

*** plane strain axial constraints

***--------------------------------------------------------------------------

** SPDISP SET = 1

1,UY , 0.00

2,UY , 0.00

...

453,UY , 0.00

***============================================================================

*** applied pressure load, min = 100, max = 1000

***============================================================================

***PRESSURE

** PRESSURE SET = 1

** 1,,,4,0, 0, 1000, 0

***============================================================================

*** applied thermal load at 77F, min = -25, max = 200

***============================================================================

*NDTEMPER

***----------------------------------------------------------------------------

*** set 1 is the applied temperature to the inner layer

*** which has a stress free temperature of 77F

***----------------------------------------------------------------------------

** NDTEMPER SET = 1

1,TEMP,77.0

2,TEMP,77.0

...

102,TEMP,77.0

51,TEMP,77.0

***----------------------------------------------------------------------------

*** set 3 is the applied temperature to the outer layer

*** which has a stress free temperature of 250F

***----------------------------------------------------------------------------

** NDTEMPER SET = 2

253,TEMP,-96.0

254,TEMP,-96.0

...

502,TEMP,-96.0

503,TEMP,-96.0

*ECHO = ON

*PRINTCNTL, ID=100

AVND,100,200,300

DISP,100,200,300

ELFO,-1

SLFO,-1

RLFO,-1

ELSE,-1

ELST,400

REAC,-1

LDVE,-1

VELO,-1

ACCE,-1

*POSTCNTL, ID=100

NDSTRS, 0

NDSTRN, 0

GPSTRS,-1

NDSTNP,-1

NDSTNC,-1

ERRIND,-1

*ENDDATA

Listing 1.4. TEXLESP2D Input For Load Case 5

$ Concyl Sample 1 Test Case

$------------------------------------------------

$ Plane Strain Compound Cylinder

$ English Units: in,lb,sec,psi

$ Load Case 5

$ Thermal Plus Pressure Loading, T=200, P=1000

$------------------------------------------------

$ Exact Solution:

$ Interface Perssure = 3074 psi

$------------------------------------------------

axisym

thermal,200

$

$------------------------------------------------

$ material definition

$------------------------------------------------

$

setup,2,ij,201

iso,lead, 1, 2.32e6, 0.44, 1.61e-5, 77

iso,steel, 2, 27e6, 0.27, 8.55e-6, 250

end,material

$

$ mesh definition

$

1,1, 101,3

1.00,1.25,1.25,1.00

0.00,0.00,0.01,0.01

101,1, 201,3

1.25,1.50,1.50,1.25

0.00,0.00,0.01,0.01

end,grid

$

$------------------------------------------------

$ element definitions

$------------------------------------------------

$

iloop,50

qq,,1, 1,1

qq,,2, 101,1

iend

$

$------------------------------------------------

$ boundary conditions

$------------------------------------------------

$

iloop,100

bc,uy, 1,1, 1

bc,uy, 1,1, 3

iend

bc,pressure, 1,1, 4, 1000.0

end,elements

$

$------------------------------------------------

$ linear solver

$------------------------------------------------

$

solve

$

$------------------------------------------------

$ post processing

$------------------------------------------------

$

stress

option,linear,15,,,,,1,1,3,3

option,linear,15,,,,,99,1,101,3

option,linear,15,,,,,199,1,201,3

end,stress

stop